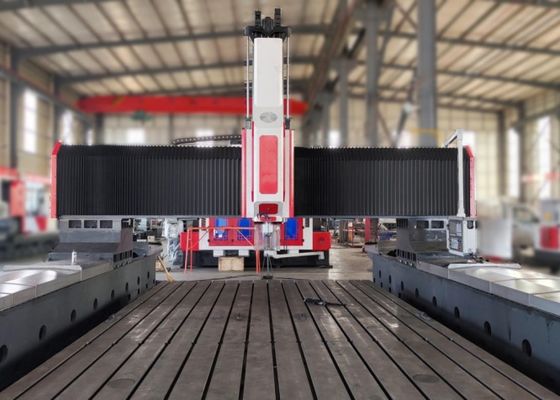

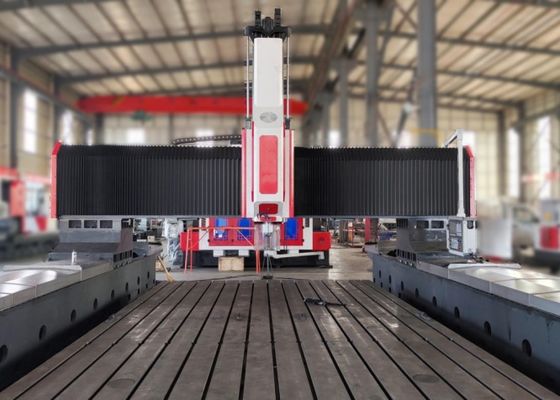

Gantry Mobile Double Spindle CNC Plate Borma ve freze makinesi modeli PHD1310

Uygulama:

Bu CNC portre tipi levha metal delme ve freze makinesi, özellikle sondaj, çemberleme, dokunma, freze,Plak iş parçaları ve yapısal bileşenler üzerinde sondaj ve sondaj işlemleriBelirtilen kalınlık aralığı içinde flanslar, diskler, halkalar ve plakalar gibi iş parçası için yüksek verimli delik işleme performansı sunar.Ekipman delikler ve kör delikler aracılığıyla işlem yapabilir, ve hem tek malzeme hem de kompozite malzemeden oluşan bileşenlerle uyumludur.Bu makine aracı üstün operasyonel rahatlık sunar ve otomatik, büyük ölçekli üretim ortamlarında çok çeşitli ürünlerin yüksek hassasiyetle üretimi.

Özellikler:

| İş parçasının boyutu |

LxW |

13000x1000 mm |

| Ganti yüksekliği |

600 mm (Ayrıca vakfına göre de belirlenebilir)

|

| Çalışma masası |

T yuvasının genişliği |

28 mm |

| Borma gücü başlığı |

Ne kadar? |

2 |

| Spindle konik |

BT1bilgi |

|

En fazla delme çapı

(Sıradan karbon çelik)

|

Φ30 mm |

| Tapping çapı |

M3-M10 |

| Döner hızı |

30~6000 r/min |

| Servo spindle motor gücü |

7.5kW |

| Spindle'in alt ucundan çalışma masasına mesafe |

200-600 mm |

|

Güç başlığının yan hareketleri(X eksen)

|

Maks. yatay yürüyüş |

1000 mm |

| Yan hareket hızı |

0 ~ 8 r/min |

| Yan hareket için servomotor gücü |

2.4kW |

|

Gantry uzunlamalı hareketi (Y ekseni)

|

Maks. besleme çarpısı |

13000 mm |

| Besleme hareket hızı |

0 ~ 8 m/min |

| Besleme servo motor gücü |

2x2.4kW |

| Dikey ram besleme hareketi (Z ekseni) |

Maks. darbe |

300 mm |

| Hareket hızı |

0~5 m/min |

| Servo motor gücü |

7.5kW (Fren) |

| Üç eksenli konumlandırma doğruluğu |

X/Y/Z/A/B/C |

±0,015/1000mm |

| Üç eksenli tekrarlanan konumlandırma doğruluğu |

X/Y/Z/A/B/C |

±0,01/1000mm |

| Toplam boyut |

LxWxH |

13000x3000x2500 mm |

Ürün Özellikleri

1Siemens/KND CNC Kontrol Sistemi:

Motor, yüksek hassasiyetli mutlak değerli servo motorlar ile çalıştırılır, RS232 arayüzü ve Çin dilinde işletim arayüzü olan renkli ekran ile donatılmıştır.hem yerinde hem de harici USB girişini desteklerken.

1.1. Kullanıcıların insan-makine arayüzü (HMI) aracılığıyla çip kırma zamanını ve döngülerini ayarlamalarını sağlayan çip kırma işlevselliği ile entegre.

1.2. Alet kaldırma fonksiyonu ile donatılmış, araç kaldırma yüksekliğinin HMI'de yapılandırılmasını sağlar.matkap parçaları atmak için iş parçasının üzerine hızla yükselir, daha sonra otomatik olarak çalışmaya başlamadan önce sondaj yüzeyine hızlı bir şekilde geri döner.

1.3Merkezi bir işletim kontrol dolabı ve bir CNC sistemi üzerinde çalışan el cihazı entegre edilmiştir.ve otomatik alarm fonksiyonları kolay programlama kolaylaştırmak için, depolama, görüntüleme ve iletişim süreçleri.

1.4Ekipman, sondaj öncesi delik konum simülasyonu ve yeniden inceleme yetenekleriyle donatılmıştır, bu da işletme kolaylığını önemli ölçüde artırmaktadır.

2Merkezi Su Sertifikası Sistemi:

Bu alet makinesinde standart merkezi bir su boşaltma sistemi vardır.Dahili püskürtme tipi su boşaltma mekanizması, makine işlemleri sırasında demir fillerin kesme aracına yapışmasını engeller, böylece alet aşınmasını azaltır, alet kullanım ömrünü uzatır ve iş parçasının yüzey finişini artırır.Kesme aleti ucunda yüksek basınçlı su boşaltması iş parçasının yüzeyini etkili bir şekilde korur, yüksek hızlı dönen eklemleri korur ve dönen bileşenlerin kirlilikten kaynaklanan tıkanmalarını önler, sonuçta iş parçasının genel kalitesini iyileştirir ve işletme verimliliğini artırır.

3Otomatik Çip Taşıyıcı ve Dönüşümlü Soğutma Sistemi:

İş masasının her iki tarafına, ucunda bir filtre yerleştirilmiş otomatik bir çip taşıyıcı yerleştirilmiştir.ve bir soğutma pompası bir tarafa monte edilmiştirSoğutma pompasının çıkışı, kauçuk bir hortum aracılığıyla merkezi su filtrasyon sistemine bağlıdır.daha sonra çip taşıyıcı pompasıyla merkezi su filtrasyon sistemine pompalandırılırFiltreli soğutma sıvısı daha sonra sondaj işlemleri sırasında soğutma sağlamak için yüksek basınçlı soğutma pompası ile dönme içine geri çevrilmektedir.Bir çip taşıma arabası da uygun çip kaldırılması için dahil edilir.

Bu yüksek performanslı CNC portre tipi levha metal delme ve işaretleme endüstriyel ekipmanı, levha tipi bileşenlerin ve yapısal parçaların hassas işlenmesi için titizlikle tasarlanmıştır.Flanşlar gibi iş parçacıklarını işlemek için özel olarak tasarlanmış, diskler, halkalar ve düz levhalar, bu iş parçalarının kalınlığının makinenin belirtilen etkili işleme parametrelerine sıkı bir şekilde uyması temel bir gerekliliktir.

Çelik yapı atölyelerinde, bu ekipmanlart, yapı plakaları ve bağlantı bileşenleri için hassas sondaj ve freze işlemleri gerçekleştirir ve böylece çelik çerçevelerin istikrarlı montajı için sağlam bir temel oluşturur.Rüzgar enerjisi endüstrisinde, rüzgar türbini kuleleri ve flanslar için yüksek hassasiyetli işleme çözümleri sunar.güçlü rüzgarlarKöprü inşaat projeleri için, ekipmanlar köprü kirişlerini ve destek desteklerini işler, bu da sabit, sabit, sabit, sabit, sabit, sabit, sabit, sabit, sabit, sabit, sabit, sabit, sabit, sabit, sabit, sabit, sabit, sabit, sabit, sabit.Köprünün uzun kullanım ömrü boyunca dinamik yüklere dayanacak şekilde tasarlanmış dayanıklı bağlantılar.

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!