3 CNC Eksenli Köşe Çelik Zımbalama Kesme Makinesi 28000*6500*2200mm Boyut Tek Bıçaklı Kesim

Uygulanabilir Sektör:

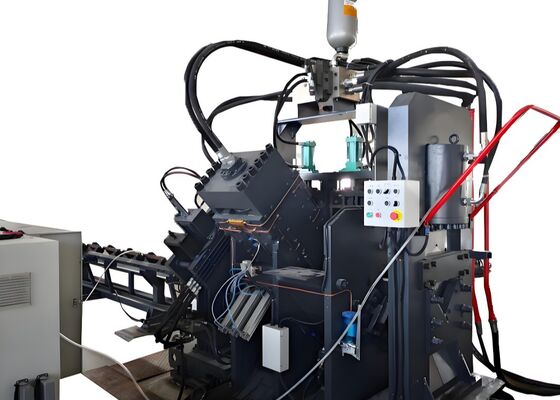

Bu CNC köşe zımbalama, kesme ve işaretleme makine hattı, köşe çeliğinin yüksek hassasiyetli zımbalama, işaretleme ve kesimi için özel olarak tasarlanmış, sektöre özgü bir sistemdir. CNC köşe çelik zımbalama makinesi, yapısal bütünlüğü ve kararlılığı sağlamak için bileşen hassasiyetinin kritik olduğu köşe çelik kule endüstrisinin temel işleme ihtiyaçlarını karşılamak üzere benzersiz bir şekilde yapılandırılmıştır.

Özellikler:

| Model |

JNC1010 |

| Fonksiyonlar |

Zımbalama, işaretleme, kesme |

| Köşe boyutu (mm) |

∟40×40×3~∟100×100×10 |

| Boşluğun maksimum uzunluğu (m) |

12 |

| Bitmiş ürünün maksimum uzunluğu (m) |

10 |

| Maks. Zımbalama (çap. х thi.) (mm) |

Φ26×10(Malzeme:Q345 510N/mm2) |

| Taraf başına zımba sayısı |

2 |

| Zımbalama kuvveti (kN) |

630 |

| İşaretleme kuvveti (kN) |

630 |

| Kesme kuvveti (kN) |

1000 |

| İşaretleme harf grubu |

4 |

| Grup başına harf sayısı |

12 |

| Harf boyutu (mm) |

14×10×19 |

| Kesme modu |

Tek bıçaklı kesim |

| CNC eksenleri |

3 |

| Köşe besleme hızı (m/dak) |

80 |

| Hidrolik sistemin soğutma yöntemi |

Su soğutma |

| İşleme hassasiyeti |

GB2694'e uygunluk |

| Program fonksiyonu |

Klavye ve USB arayüzü ile giriş |

| Boyut (mm) |

28000×6500×2200 |

Ürün Bileşimi:

Bu CNC zımbalama, kesme ve işaretleme sistemi, öncelikle enine konveyör, döner yükleme mekanizması, besleme konveyörü, CNC besleme arabası, zımbalama ünitesi, işaretleme ünitesi, kesme ünitesi ve boşaltma konveyörünü içeren temel işlevsel modüllerden oluşur. Ek olarak, köşe zımbalama makine hattı, hidrolik, elektrik ve pnömatik sistemler gibi temel destek sistemlerini ve çeşitli yardımcı bileşenleri entegre eder.

Ürün Özellikleri:

1. İşaretleme Ünitesi Tasarımı

İşaretleme ünitesi, üstün sağlamlık sağlayan sağlam bir kapalı çerçeve yapısına sahiptir. Program aracılığıyla seçilebilen dört set karakter kutusu ile donatılmıştır. Referans işaretleme konumu, özel gereksinimleri karşılamak için serbestçe ayarlanabilir.

2. Zımba ve Kalıp Kurulumu

CNC zımbalama ve kesme makine hattı, her iki tarafta üç farklı zımba çapını işleyebilen üç set zımba ve kalıp ile donatılmıştır. PLC sistemi tarafından kontrol edilen üç set kalıp, gerektiğinde zımbalama referans konumunu ayarlamak için senkronize olarak hareket edebilir.

3. İnsan-Makine Arayüzü ve Programlama

Sistem, sezgisel kullanım için tasarlanmış ve iş parçası diyagramlarını görüntüleyebilen iki dilli (Çince/İngilizce) bir arayüz ile donatılmıştır. Programlama basitleştirilmiştir, makinenin CAD yazılımı tarafından oluşturulan program verilerini doğrudan kullanmasına olanak tanır. Program düzenleme sırasında, kullanıcıların yalnızca iş parçası boyutlarını, delik çaplarını, referans işaretlerini ve miktarları girmesi gerekir.

4. Kontrol ve Besleme Sistemi

Kuleler için CNC zımbalama ekipmanı, gelişmiş CNC teknolojisi ve servo motorlu besleme kullanır, gelişmiş operasyonel verimlilik ve tutarlı iş parçası doğruluğu sağlar. Tüm kritik hidrolik, pnömatik ve elektrik bileşenleri, güvenilir sistem performansı garanti eden tanınmış uluslararası tedarikçilerden temin edilmektedir.

Köşe çelik kule endüstrisindeki yaygın özellikler ve işleme gereksinimlerini temsil eden bu örnekler, kullanıcıların ekipmanın işleme kalitesini, hassasiyetini ve işçilik standartlarını doğrudan değerlendirmesine olanak tanır.

Kulelerin aşırı hava koşullarına ve ağır yüklere dayanması gereken ultra yüksek gerilim (UHV) iletim hatlarının inşasında, bu ekipman, kulelerin temel çerçevesini oluşturan köşe çelik bileşenlerin işlenmesinde çok önemli bir rol oynar. Kule gövdelerinde, çapraz kollarda ve diğer kritik yapısal elemanlarda kullanılan köşe çeliği üzerinde sürekli olarak delme ve damgalama işlemleri gerçekleştirir. Bu, hassas boyutsal doğruluk ve güçlü bağlantılar sağlayarak, kulelerin genel stabilitesini korur.

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!