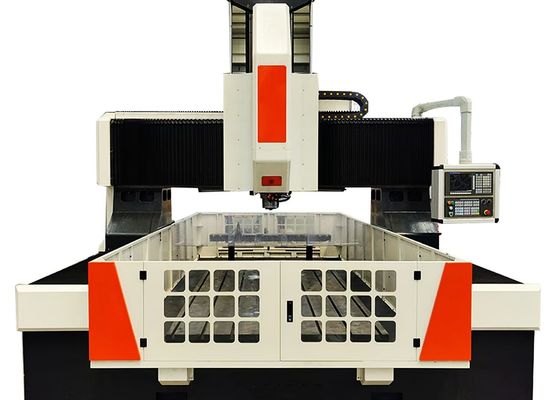

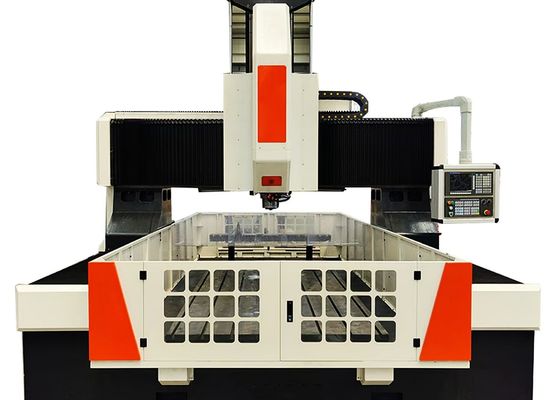

180mm Max Thickness CNC Gantry Plate Flange Drilling Machine M3-M24mm Tapping Diameter

Application:

This equipment is specifically engineered to perform drilling, chamfering, tapping, and milling operations on plate-type components and structural parts. It is primarily deployed for the high-efficiency drilling of workpieces such as flanges, discs, rings, and plates—provided that the thickness of these workpieces falls within the effective processing range. The device enables the drilling of both through holes and blind holes in single-material components as well as composite materials. The machining process of this machine tool is controlled by digital technology, which guarantees a high degree of operational convenience. It is capable of meeting the requirements of automated production, high-precision machining, multi-variety manufacturing, and mass production.

Specifications:

| Workpiece size |

LxW |

1200x1200 mm |

| |

Gantry height |

600 mm |

| workbench |

T-slot width |

28mm |

| Drilling power head |

Qty. |

1 |

| Spindle taper |

BT50-150 |

| Max.drilling diamter |

Φ50 mm |

| Max.thickness |

≤180 mm |

| Tapping diameter |

M3-M24 mm |

| Spindle speed |

30~3000 r/min |

| Servo spindle motor power |

11kW |

| Distance from the lower end of the spindle to the worktable |

200-600mm |

|

Lateral movement of power head

(X axis)

|

Max.horizontal stroke |

1200 mm |

| Lateral movement speed |

0~8 r/min |

| Servo motor power for lateral movement |

1x2.4 kW |

| Gantry longitudinal movement (Y axis) |

Max. feed stroke |

1200 mm |

| Feed moving speed |

0~8 m/min |

| Feed servo motor power |

2x2.4 kW |

| Vertical ram feed motion (Z axis) |

Max. stroke |

400 mm |

| Moving speed |

0~8 m/min |

| Servo motor power |

1x2.4 kW |

| Three-axis positioning accuracy |

X/Y/Z/A/B/C |

±0.015/1000mm |

| Three-axis repeat positioning accuracy |

X/Y/Z/A/B/C |

±0.01/1000mm |

Machine Structure

This machine is primarily composed of core components, including a bed workbench, a movable gantry, a movable sliding saddle, a drilling and milling power head, an automatic lubrication unit, a protective mechanism, a circulating cooling system, a numerical control system, and an electrical system, among others. It adopts a rolling guide pair for support and guidance functions, and is driven by a precision lead screw pair. As a result, this machine tool demonstrates high positioning accuracy and excellent repeat positioning accuracy.

Product Features

1. Automatic Lubrication Device and Protective Device

This machine tool is fitted with an original volumetric partial-pressure automatic lubrication device sourced from Taiwan. This device delivers automatic lubrication to all kinematic pairs—including guide rails, lead screws, and racks—without leaving any unlubricated dead zones, effectively extending the service life of the machine tool. The X-axis and Y-axis of the machine tool are equipped with dust-proof protective covers, while waterproof splash guards are installed around the workbench to enhance operational protection.

2. Automatic Chip Conveyor and Circulating Cooling Device

An automatic chip conveyor is integrated at the rear of the workbench, with a filter unit installed at its terminal end. The automatic chip conveyor adopts a flat-chain design. A cooling pump is mounted on one side of the machine, and its outlet is connected to the central water filtration system via a flexible hose. The coolant flows into the chip conveyor first; subsequently, the chip conveyor’s lift pump transfers the coolant to the central outlet filtration system. After filtration, the high-pressure cooling pump circulates the coolant to provide cutting cooling. Additionally, a scrap-transporting trolley is equipped to facilitate the convenient handling and removal of iron scraps.

3. Laser Interferometer

Every unit of this equipment is subjected to calibration using an API laser interferometer (sourced from the United States). This calibration process enables accurate inspection and compensation of key performance indicators, including pitch error, backlash, positioning accuracy, and repeat positioning accuracy. Such rigorous calibration ensures the machine’s dynamic and static stability, as well as its machining precision.

The CNC gantry drilling and milling machine is a high-performance industrial asset purpose-engineered for the precision machining of plate-type components and structural parts. This equipment is tailored for processing workpieces such as flanges, discs, rings, and plates—with the critical prerequisite that the thickness of these workpieces strictly complies with the machine’s specified effective machining range.

Within steel structure workshops, it delivers precise drilling and milling operations for structural plates and connectors, laying a solid foundation for the robust assembly of steel frames. For wind power applications, it performs high-precision processing on wind turbine towers and flanges—a critical requirement to ensure these components can withstand harsh operating conditions (e.g., strong winds, temperature fluctuations). In bridge construction, it undertakes the machining of girders and brackets, guaranteeing stable and durable connections capable of withstanding dynamic loads throughout the bridge’s long-term service life.

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!